Manufacture Matter-Enabled ACK Devices

After you complete your Alexa Connect Kit (ACK) Matter prototype and receive certification, you can manufacture and launch your product. To manufacture your device with the ACK module, you add ACK-specific steps to your manufacturing line, such as provisioning the device with Matter credentials.

Manufacturing prerequisites

Before you manufacture your ACK-based Matter device, make sure that you complete the following tasks:

- Create design validation test (DVT) samples to test your manufacturing process and the quality of your samples.

- Confirm with the ACK hardware team that the ACK-related hardware design of the DVT sample meets Amazon requirements.

- Finalize your firmware by completing the following items:

- Verify that you removed debug code.

- Certify your Matter product with Connectivity Standards Alliance (CSA) Certification. After certification, CSA provides you with a Certification Declaration (CD).

- Certify your product with the Works with Alexa (WWA) and Frustration-Free Setup (FFS) Amazon programs.

- Verify that your prototype works with over-the-air (OTA) updates.

- Verify that you can access metrics collected from your devices and stored in an Amazon Web Services (AWS) S3 bucket. Your ACK support engineer can share access to the metrics and logs with your AWS developer account.

- Verify that you can trigger log collection from your device and access the collected logs from your AWS S3 bucket.

- Complete a security review with the Amazon team.

Manufacturing with ACK

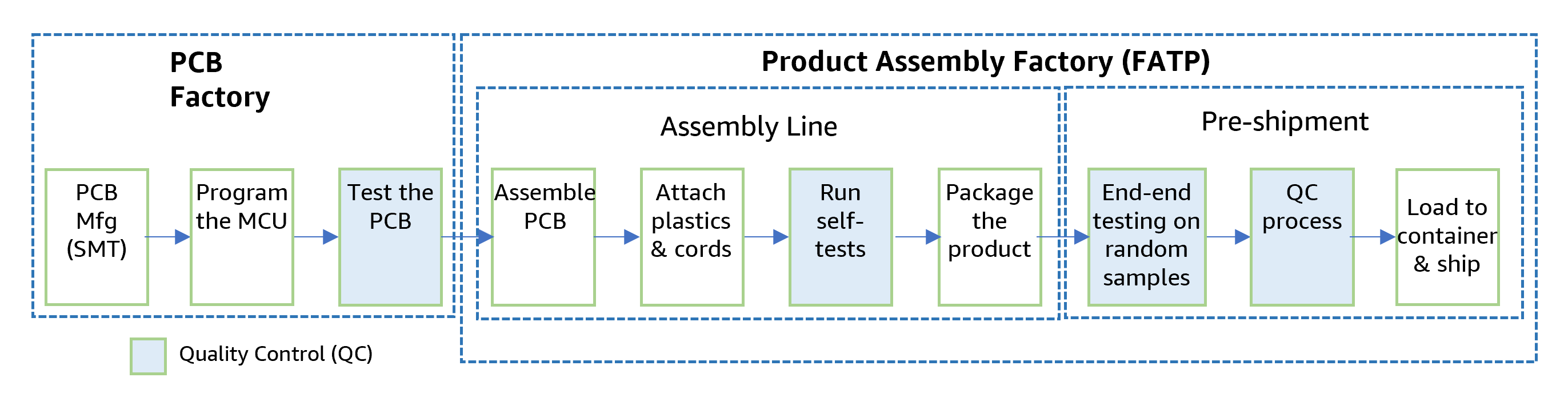

The following diagram shows a typical manufacturing flow for devices that don't connect to smart assistants.

Add ACK steps to the production line

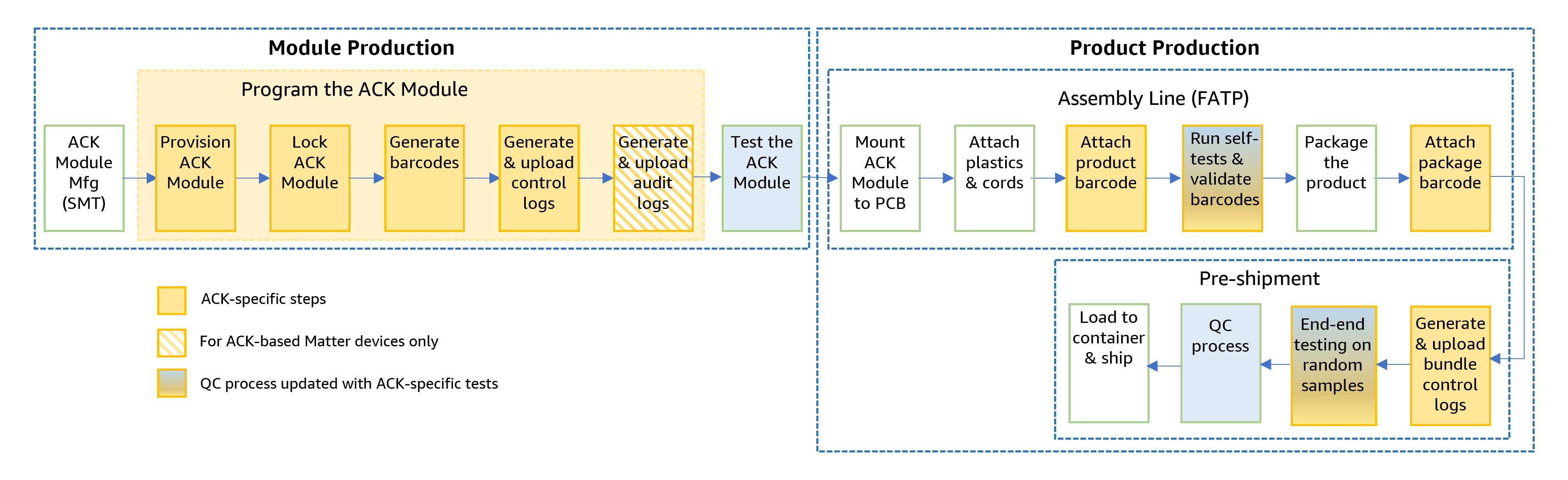

To manufacture ACK-based devices built with the ACK SDK or ACK SDK for Matter, you add the following ACK-specific steps to your module and product production phases.

- Module production – Program and lock the ACK module, generate barcodes or QR codes for the device and package, and generate and upload device control logs for FFS. For Matter-enabled devices, generate and upload audit logs.

- Product production - Assembly line final assembly, test, and pack (FATP) – Attach the product and package barcodes and validate these against the generated barcodes. Test full user functionality of the first product to verify the production process is correct.

- Product production - pre-shipment – If you sell a device as part of a multi-device package (bundle), generate and attach the bundle barcode and gather and upload bundle control logs. Run end-to-end testing on random samples to validate Alexa features.

The following diagram shows the updated manufacturing flow for ACK-based Matter devices that connect to smart home assistants.

Store production data

The production process requires tracking and storing product-related information across multiple steps. Amazon recommends that you use a secure data storage solution that operates both locally and on remote servers. The System Integrator (SI) maintains and secures the primary data store. This data store serves the following purposes:

- Stores product information for reference during production.

- Allows you to add device and package barcodes and other codes.

- Enables you to monitor and update production verification processes.

- Allows you to supervise bundle device shipments.

Original Design Manufacturers (ODMs) handle local data collection during production. Key activities include verifying printed barcode, audit logs, control logs, and various product identifiers, as well as updating verification results.

Throughout the manufacturing process, you save the generated information for each module in the data store, including the following required device information:

- Module ID (MAC)

- Vendor name

- Product name

- Device type ID

- Matter Vendor ID

- Matter Product ID

- Advertised Product Id (APID)

- Device QR code (Matter QR code or ACK inner barcode)

- Device QR code verification result

- Package barcode

- Package barcode verification result

- Device control log

- Device control log upload result

- Product unique IDs (UPC, EAN, FNSKU, or other)

- Product IDs verification result

- Bundle control log, for multi-device packages only

- Bundle control log upload result

Given that some factories have limited network connectivity, Amazon recommends that you use an offline database on the production line. Then, synchronize the data with the online database periodically rather than in real-time. ODMs can store information locally and update the online database one time a day or after each production run. For facilities without network access, the SI should establish a method to collect production data before shipment.

Requirements and best practices

To manufacture ACK-based devices, review the following requirements and best practices.

Requirements for manufacturing

To manufacture ACK-based devices built with the ACK SDK or ACK SDK for Matter, you must meet the following requirements.

- Amazon uses control logs to track the encoded identifier of a device or device bundle for Frustration Free Setup (FFS). Amazon requires you to upload device and multi-device package (bundle) control logs during manufacturing. For more details, see Upload Production Logs.

Tip: To avoid manual upload, Amazon recommends that you implement an automatic update and feedback mechanism.

- For Matter devices, Amazon uses audit logs to track the provisioning record of each device. Amazon requires you to upload audit log 24 hours after provisioning the module. For more details, see Upload Production Logs.

Tip: To avoid missing the 24-hour window, Amazon recommends that you implement an automatic update mechanism.

-

Use a secure and reliable database, Excel file, or some other mechanism to securely store and update device information. Upload known module data before module programming and upload new data generated during the manufacturing process. For required data, see production data.

- A set of ACK-based production tools, user guides, and related training for ODM manufacturers. Include at least product codes printing, product codes validation, bundle device creation, control log upload and feedback acquisition. You can use the following resources to help build your production tools:

- Generate barcodes commands.

- Barcode verification tool to verify barcodes for your device type ID.

https://developer.amazon.com/frustration-free-setup/console/products/<device_type_id>/barcode-verification - Audit log upload automation.

- Control log generation commands.

- Control log upload automation.

-

The product barcode and package barcode are crucial for product registration, including manual scanning and FFS. During the production process, make sure that the product barcode and package barcode correspond to the product. Amazon recommends that you use Bluetooth broadcast information to confirm the product barcode, and scan all barcodes of the product to compare and confirm with the original data generated during the provisioning process.

-

Store all barcodes and UPC/EAN of a product in the database. On the production line, scan all barcodes of a product and compare them with the barcodes in the database to determine if they match. Any barcode error can cause trouble for end users, and in serious cases, might cause Alexa to become unavailable.

- Confirm successful device and bundle control log upload before product shipment.

Best practices for manufacturing

Amazon recommends the following best practices for manufacturing ACK-based devices.

-

Use the client-server provisioning model for a more secure production of devices. For more details, see Set Up Client - Server Machines for Production.

-

Use a dedicated file tracking mechanism, such as a project lifecycle management system, for R&D and production-line documents and a fixed address on the server to store these documents. Keep records of each update, including version number, and archive previous versions.

-

Provide a manufacturing flow with ACK-specific steps. A System Integrator (SI) or someone with experience in developing and producing ACK products can provide guidance for manufacturing the initial ACK-based product and changes when product plans or product types changes. Review your manufacturing plan with Amazon.

-

Store and backup the device information offline.

-

Verify a set of devices in a production to make sure that the Alexa and Matter features work. Make sure that you do a factory reset of these devices before shipment. If you do an FFS test on a device, don't ship that device.

Add ACK-based steps to your manufacturing line

Throughout the manufacturing process, save the generated information for each module in the database. Make sure you store all required data.

Module production

Before you start, set up your client and server machines for module production. Then, complete the following ACK-specific steps for module production.

- Provision test ACK modules.

- Provision ACK modules.

- Lock ACK modules.

- Generate and save barcodes.

- Generate and upload device control logs.

- Upload audit logs generated during provisioning. (Matter devices only.)

- Validate the device control log and audit log uploads and update the result to the database.

Product production

Complete the following ACK-specific product production steps to produce, package, and ship your ACK-based product.

- Print and attach the device barcode or QR code (Matter devices) to the module during the assembly process.

- Validate the barcode on device matches the ID that the ACK module transmits. Use the product Bluetooth broadcast information to obtain the module ID and compare the module ID and the scanned device barcode with the information stored in the database. Make sure that these match, and then update the result to the database.

- Test full user functionality of the first product to verify the production process is correct. Verify the following features.

Warning: Don't ship products that went through the FFS process. These devices won't work for customers.

- The device barcode or QR code using the FFS barcode verification tool.

- Product registration, auto-discovery, and device-deletion in the Alexa app. For more details, see Commission ACK-based Matter Devices.

- Product control with voice, the Alexa app, and manually on the device.

- Print and attach the package barcode to the device package or bundle package.

- Validate the all printed barcodes and UPC/EAN codes match the information stored in the database. Update the result to the database.

- Test random samples to verify Alexa and ACK features, excluding FFS. Amazon recommends that you sample 1–5 products per 1000 produced.

Important: You must factory reset these samples before you ship.

- Generate and upload bundle control logs, if applicable.

- Validate the device and bundle control log uploads before you ship bundled products. Update the result to the database.

Related topics

- Frustration-Free Setup Barcode Specification

- Frustration-Free Setup Control Logs

- Provision ACK-based Matter Prototype Devices

Last updated: frontmatter-missing